Kupanga PVC

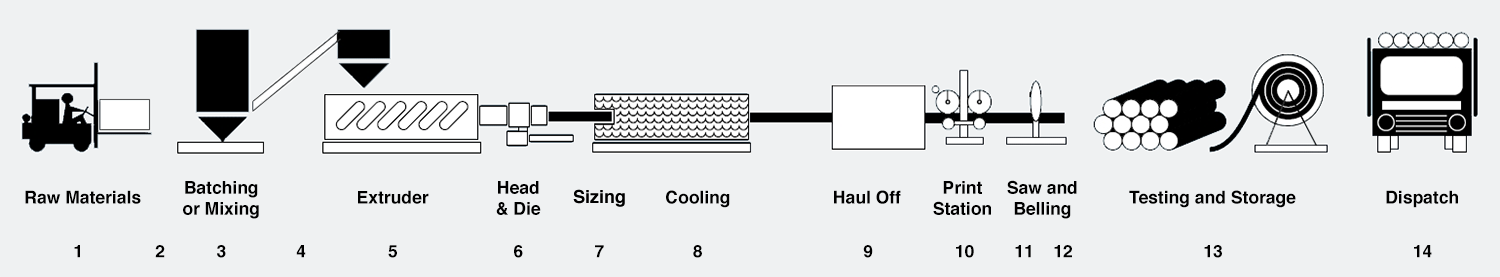

Kwenikweni, zinthu za PVC zimapangidwa kuchokera ku ufa wa PVC waiwisi ndi njira ya kutentha ndi kupanikizika.Njira ziwiri zazikulu zomwe zimagwiritsidwa ntchito popanga ndi extrusion ya chitoliro ndi jekeseni akamaumba zolumikizira.

Kukonzekera kwamakono kwa PVC kumaphatikizapo njira zasayansi zotukuka kwambiri zomwe zimafuna kuwongolera kusinthasintha kwamachitidwe.Zinthu za polima ndi ufa wopanda pake, womwe umafunika kuwonjezeredwa kwa zolimbitsa thupi ndi zothandizira kukonza.Kupanga ndi kusakanikirana ndi magawo ofunikira a ndondomekoyi ndipo zomveka zolimba zimasungidwa kwa zipangizo zomwe zikubwera, kusakaniza ndi kusakaniza.Kudyetsa kwa extrusion kapena kuumba makina kungakhale mwachindunji, mwa mawonekedwe a "kusakaniza youma", kapena pre-processed mu granular "compound".

Extrusion

Polima ndi zowonjezera (1) amayezedwa molondola (2) ndi kukonzedwa kupyolera mu liwiro lapamwamba kusakaniza (3) kusakaniza zopangira mu osakaniza anagawira youma osakaniza osakaniza.Kutentha kosakanikirana kozungulira 120 ° C kumatheka ndi kutentha kwamphamvu.Pamagawo osiyanasiyana osakanikirana, zowonjezera zimasungunuka ndikuyika pang'onopang'ono ma granules a PVC polima.Pambuyo pofika kutentha komwe kumafunikira, kusakanizako kumangotulutsidwa m'chipinda chozizira chomwe chimachepetsa kutentha kufika pafupifupi 50 ° C, motero zimalola kuti kusakaniza kulowetsedwe kumalo osungirako apakati (4) kumene ngakhale kutentha ndi kusasinthasintha kumatheka.

Mtima wa ndondomekoyi, extruder (5), imakhala ndi mbiya yoyendetsedwa ndi kutentha, yozungulira yomwe imazungulira molondola "zomangira".Zomangira zamakono za extruder ndi zida zovuta, zopangidwa mosamala ndi ndege zosiyanasiyana kuti ziwongolere kuponderezana ndi kukameta ubweya, zomwe zimapangidwa pazinthuzo, panthawi yonseyi.Kukonzekera kwapawiri kozungulira kozungulira komwe kumagwiritsidwa ntchito ndi opanga onse akuluakulu kumapereka kukonza bwino.

Dryblend ya PVC imayikidwa mu mbiya ndi zomangira, zomwe zimasinthira kusakaniza kowuma kukhala "kusungunuka" kofunikira, ndi kutentha, kupanikizika ndi kumeta ubweya.Panthawi yodutsa pazitsulo, PVC imadutsa madera angapo omwe amapondereza, homogenise ndikutulutsa mtsinje wosungunuka.Malo omaliza amawonjezera kukakamiza kuti atulutse chisungunuko kudzera pamutu ndi kufa (6) chomwe chimapangidwa molingana ndi kukula kwa chitoliro chofunikira komanso mawonekedwe otaya a mtsinje wosungunuka.Chitolirocho chikachoka ku extrusion kufa, imakulitsidwa podutsa m'manja olondola kwambiri okhala ndi vacuum yakunja.Izi ndi zokwanira kuumitsa kunja wosanjikiza wa PVC ndi kugwira chitoliro m'mimba mwake pozizira komaliza m'zipinda zoziziritsira madzi zoyendetsedwa bwino (8).

Chitolirocho chimakokedwa potengera kukula ndi kuziziritsa ndi chokoka kapena kutulutsa (9) mwachangu.Kuwongolera liwiro ndikofunikira kwambiri pamene chidachi chikugwiritsidwa ntchito chifukwa liwiro lomwe chitoliro chimakokera chimakhudza makulidwe a khoma la chinthu chomalizidwa.Pankhani ya mphira mphete jointed chitoliro ndi kukoka-kuchoka anachedwa pa intervals yoyenera kuti thicken chitoliro m`dera la zitsulo.

Chosindikizira cham'mizere (10) chimayika mapaipi pafupipafupi, ndikuzindikiritsa molingana ndi kukula, kalasi, mtundu, tsiku, nambala yokhazikika, ndi nambala ya extruder.Makina ocheka okha (11) amadula chitolirocho mpaka kutalika kofunikira.

Makina a belu amapanga soketi kumapeto kwa utali uliwonse wa chitoliro (12).Pali mitundu iwiri ya socket.Kwa chitoliro chophatikizika cha rabara, mandrel ogonja amagwiritsidwa ntchito, pomwe mandrel wamba amagwiritsidwa ntchito ngati zosungunulira zolumikizana.Chitoliro cha mphete cha mphira chimafuna chamfer pa spigot, yomwe imachitidwa pa macheka kapena belling unit.

Chomalizidwacho chimasungidwa m'malo osungira kuti chiwunikidwe ndikuyesedwa komaliza kwa labotale ndikuvomerezedwa bwino (13).Zopanga zonse zimayesedwa ndikuwunikidwa molingana ndi Standard Australian Standard komanso/kapena kutengera zomwe wogula.

Pambuyo poyang'anitsitsa ndi kuvomereza, chitolirocho chimasungidwa kuti chidikire kutumiza komaliza (14).

Kwa mapaipi opangidwa ndi PVC (PVC-O), njira yowonjezera imatsatiridwa ndi njira yowonjezera yowonjezera yomwe imachitika pansi pamikhalidwe yodziwika bwino komanso yoyendetsedwa bwino ya kutentha ndi kupanikizika.Ndi panthawi yowonjezereka pamene ma cell orientation, omwe amapereka mphamvu zambiri za PVC-O, zimachitika.

Jekeseni Kumangira

Zopangira PVC zimapangidwa ndi jekeseni wothamanga kwambiri.Mosiyana ndi extrusion mosalekeza, akamaumba ndi mobwerezabwereza cyclic ndondomeko, kumene "kuwombera" zinthu amaperekedwa ku nkhungu mkombero uliwonse.

Zida za PVC, zomwe zimakhala zowuma zowuma kapena zophatikizika ndi granular, ndi mphamvu yokoka yomwe imadyetsedwa kuchokera ku hopper yomwe ili pamwamba pa jekeseni, kulowa mu mbiya yotsekera.

Mgolowu umayimbidwa ndi kuchuluka kofunikira kwa pulasitiki ndi zozungulira zozungulira ndikutumiza zinthuzo kutsogolo kwa mbiyayo.Malo a screw amayikidwa kuti akhale "kukula kwa kuwombera".Panthawi imeneyi, kupanikizika ndi kutentha "pulasitiki" zinthu, zomwe tsopano zasungunuka, zikuyembekezera jekeseni mu nkhungu.

Zonsezi zimachitika panthawi yozizira ya kuwombera koyambirira.Pambuyo pa nthawi yoikidwiratu nkhungu imatsegulidwa ndipo chomaliza chopangidwacho chidzachotsedwa mu nkhungu.

Chikombolecho chimatseka ndipo pulasitiki yosungunuka kutsogolo kwa mbiya imabayidwa pansi pa kupsyinjika kwakukulu ndi screw yomwe tsopano ikugwira ntchito ngati plunger.Pulasitiki imalowa mu nkhungu kuti ipange chotsatira chotsatira.

Pambuyo jekeseni, recharge imayamba pomwe choyikapo chimadutsa m'nyengo yozizira.

Nthawi yotumiza: Jun-23-2022